Solution

An Automation Solution for Manufacturing Sites

MATE-POP

(Point of Production)

(Point of Production)

Production Time Management System

Product overview

Product overviewA standardized ‘point of production’ management system for production activities in manufacturing plants This is a solution that works to eliminate many of the inefficiencies resulting from the inability of many manufacturing companies to quickly and accurately gather information related to production activities.

MATE-POP manages all sorts of different information related to production activities in real time, providing information that can be used as company administration indicators, management, and business information.

By building a system at a low cost based on templates for each industry and allowing that system to be applied quickly, MATE-POP minimizes the customer's investment burden and minimizes the chance of any failures arising from to the application of a new system while maximizing the effect that comes with its application.

By building a system at a low cost based on templates for each industry and allowing that system to be applied quickly, MATE-POP minimizes the customer's investment burden and minimizes the chance of any failures arising from to the application of a new system while maximizing the effect that comes with its application.

The Need for POP

The Need for POP- The existing system cannot be used normally.

- Managing production performance information is difficult.

- Fault registration is inconvenient.

- It is difficult to determine the status of production progress.

- Data is not very reliable for managing production costs.

Product Features

Product Features-

01

Real-time collection, analysis, and monitoring of various information produced at production sites -

02

Production information can be collected in both semi-auto mode and fully automatic mode -

03

Mobile sales management makes sales possible anytime, anywhere

System Configuration

System Configuration

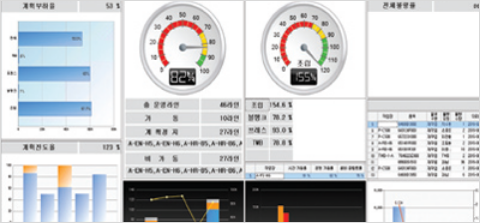

Expected Effects

Expected EffectsMATE-POP enables the collection and optimal management of the production activity statuses of the ‘4 Ms’ that exist on production sites in real time through the information system. The term ‘4 Ms’ refers to the operator (manpower), production method (method), materials (materials), and production facility (machines).

-

01

Real-time on-site monitoring

Management for equipment failures and non-operation Information on operational delays and material shortages Minimizes the idle time of equipment based on aggregate data by equipment/worker/employee number The acquired production history allows for long-term planning and knowledge accumulation Shows work-in-progress information for the production site -

02

Data reliability

Information on secured production results is processed in real time, increasing the reliability of data -

03

Lot tracking management

Everything from materials to sales, customer shipments, and post-shipment returns can be managed. -

04

Raw material/finished product management

Inventory management of raw materials and products, payment management, and outsourcing inventory management -

05

Identifies problems at the production site

Allows quick, flexible responses to manufacturing problems such as yield, equipment operation rate, product quality, etc. -

06

Cost reduction

Everything from materials to sales, customer shipments, and post-shipment returns can be managed. -

07

Customer satisfaction

Improves customer satisfaction, shortens customer response time

Business

Business-

Automobile

Automobile

parts

manufacturing -

Electric and

Electric and

electronic -

Pharmaceutical

Pharmaceutical

chemistry -

Equipment

Equipment

automation -

Other general

Other general

manufacturing

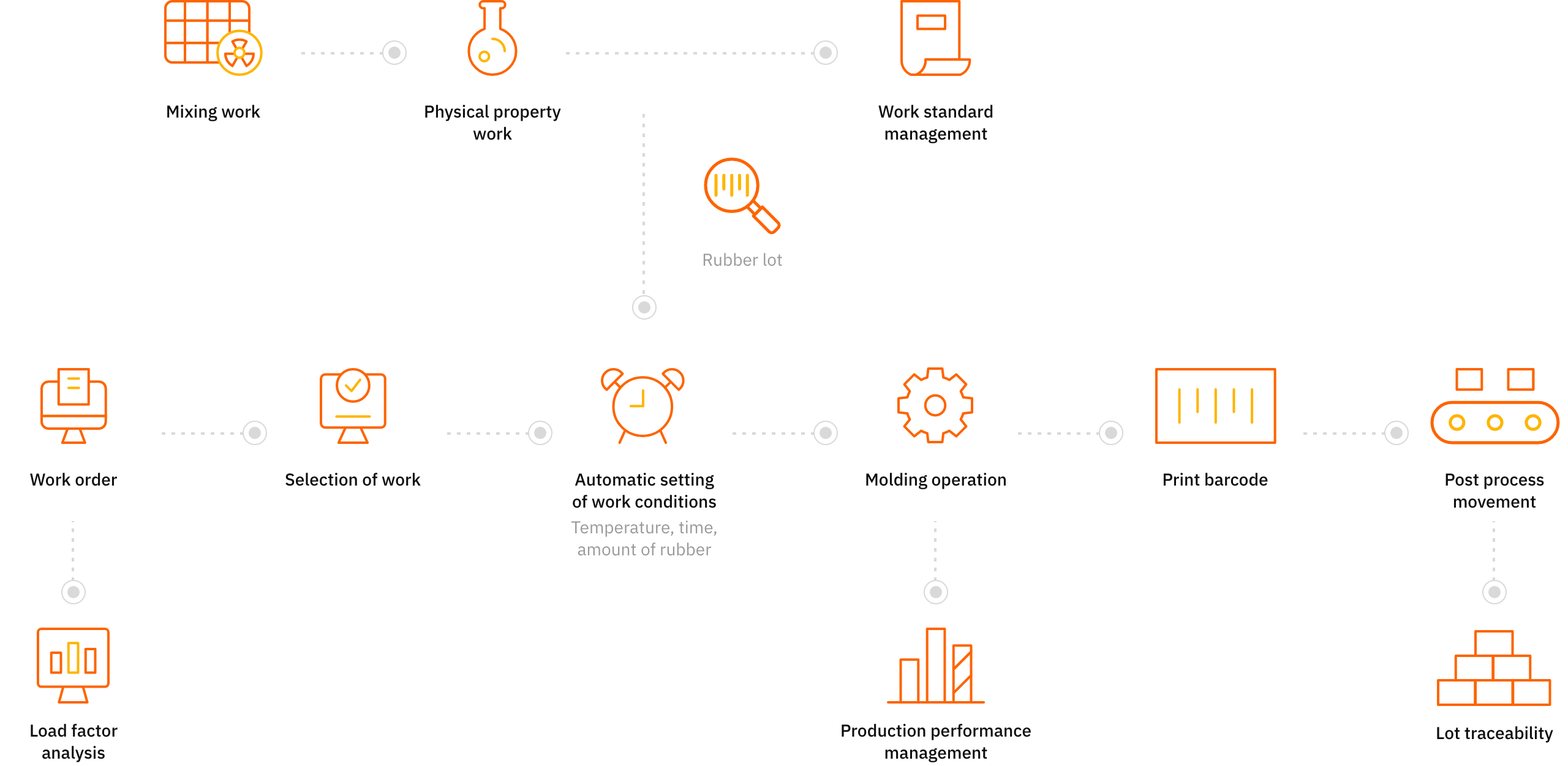

Automobile parts industry

All parts and manufacturing businesses related to rubber molding, compounding rubber, painting, plating, sewing, electronics, wiring, injection molding, welding, casting/forging, heat treatment, and soldering

MATE-POP Main Functions and Implementation Display

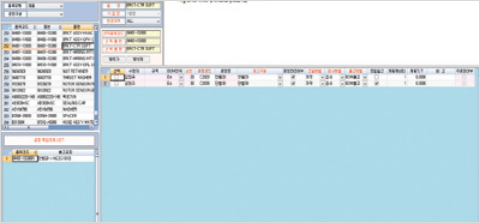

MATE-POP Main Functions and Implementation DisplayERP Connection

- By connecting with the existing information systems or ERP systems in operation, the production planning information is automatically received from a host system and used as production instruction information. On-site production performance, quality information, etc. can also be linked via higher-level systems (connection can also be made with various well-known ERP systems both domestically and abroad)

Standard information management

- Standard information can be received from a higher-level system and used in MATE-POP. Information that is not managed by a higher-level system, such as equipment code/ fault code/ quality defect codes, can be managed independently.

- If no higher-level system is configured or if one is incomplete, MATE-POP alone can establish a production plan and schedule and is usable with just the input of standard information.

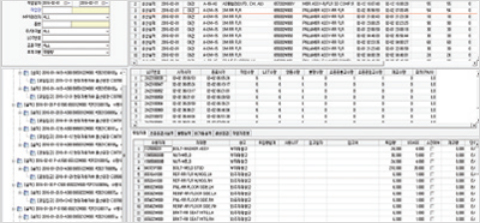

Production status management

- Provides real-time information on the production status of work sites in various forms, which is impossible with most ERP systems. This information includes the analysis of production performance by product/process/work order/time period and performance against target.

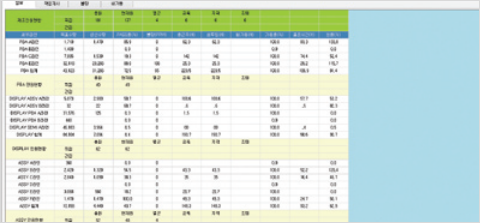

Analysis of quality information

- Effective quality management is made possible via real-time analysis of various quality-related information, such as occurrence status and defect rate management by product/resource, the top 10 statuses relating to defects by product/resource and share of total defects, analysis of rework/scrap occurrence information, and trend analysis of defect occurrences by date/resource through graphs, etc.

Productivity analysis

- In order to determine whether things are operating efficiently with regard to the human resources allocated to production activities, information on a vast amount of information through attendance management/labor analysis and comprehensive productivity analysis targeting on-site employees is analyzed and provided, allowing managers to manage multiple different forms of data.

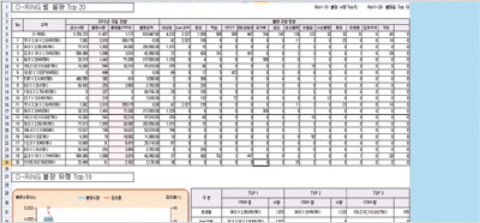

Management of production facilities

- Used as basic data for establishing a facility maintenance plan by providing analysis information through various types of graphs detailing the status of facility abnormalities, management of top 10 failures, facility operation rate, and failure trends by type

- Efficient facility management is achieved via the real-time collection of on-site failure/non-operation information, etc.

Monitoring of production status

- Real-time viewing/monitoring of a production site in real time

- Composed of display with graphics that move like a production line being moved to a computer.

- Collects information by connecting with control devices such as PLC, etc. that are installed on-site

- Through the integration of domestic and overseas HMI (MMI) software, the Internet can be used to monitor the production status in real time even outside the factory.

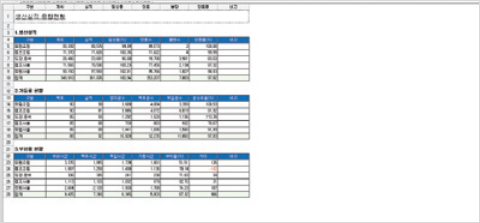

Lot management

- By increasing lot tracking precision, accurate history management, forward/reverse lot tracking, identical lot shipment data tracking, and identical material lot tracking are all possible.

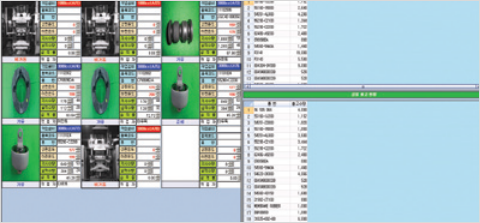

Production monitoring

- MATE-POP was designed to let users understand at a glance the real-time monitoring of their production sites. It does this by providing the same monitoring screen as the one in the on-site facility, detailed monitoring displays for each facility, and details on materials/sales/goods in processing/goods in stock/goods sent out. This enables production managers and employees to determine the production status at a glance without going to the production site in person.

Please leave an inquiry

with your COMPUTERMATE specialist.