Solution

An Automation Solution for Manufacturing Sites

(Quality Management Systems)

Product Overview

Product Overview Product Feature

Product Feature-

Continuous monitoring

of quality information -

Quality LOT tracking automation

-

Identify the cause of quality problems

with various analysis functions -

Creates various reports related

to quality, e.g. the cause of defects

MATE-QMS Function

MATE-QMS Function-

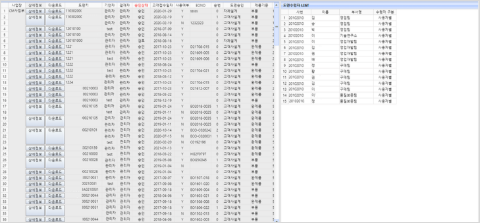

Reference

managementItem master

Customer master

Department information

Monthly unit price registration

Defect code registration

Validation inspection list registration

-

Drawing

managementDrawing registration

Design modification and history management

Drawing status inquiry

-

Development

managementComprehensive status of RFQ and development request

Development phase registration and settings

Development registration

Progress management registration

-

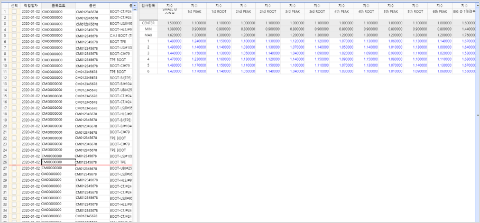

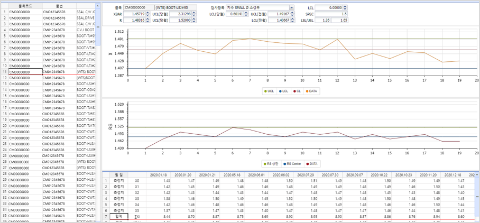

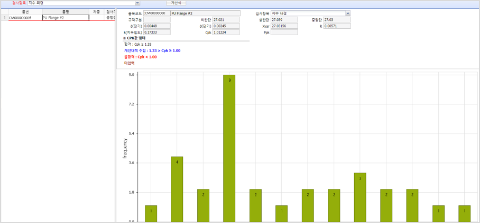

SPC

managementSPC reference registration

SPC reference inquiry

SPC performance registration

SPC performance inquiry

X-BAR management

Process capability management

-

Instrument

managementReference management

Instrument mater registration

Instrument master inquiry

Instrument planning and performance registration

Inspection and calibration schedule and cost

Instrument inspection and calibration status

-

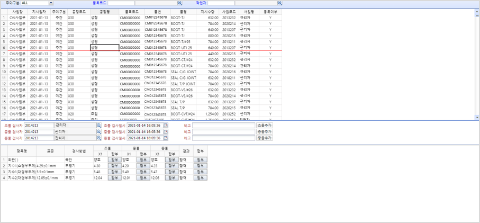

Defect

managementDefect registration

Defect status inquiry

Monthly defect status

Yearly defect status

-

Inspection

managementInitial-mid-final inspection management

Initial-mid-final reference registration

-

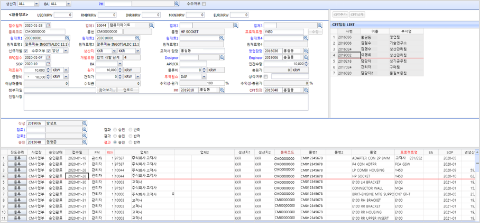

Corrective action and

countermeasureCorrective action request receipt

Countermeasure registration

Countermeasure approval and review

Validity inspection

Management of problems of past projects

Application status of problems of past projects

-

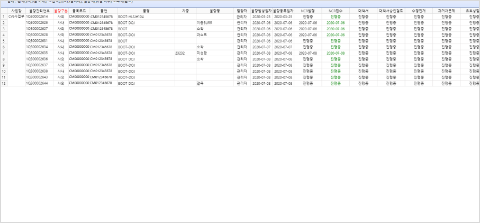

4M revision

management/ISIR4M revision report

4M revision receipt (material receipt)

4M revision receipt (quality receipt)

4M revision report reply

4M revision report result inquiry

ISIR registration

-

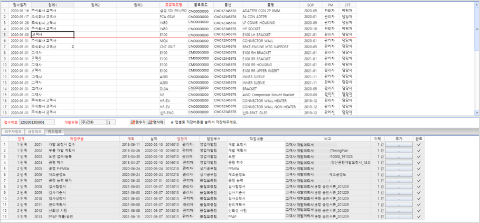

Parts regular inspection

managementMain parts management

Regular parts inspection planning registration

Comprehensive status of regular parts inspection

Regular parts inspection approval

Regular parts inspection inquiry

-

Reliability test

managementReliability test name registration

Reliability test specification registration

Reliability test planning inquiry

Reliability test planning inquiry (by testing)

Testability analysis request

-

Partner

qualityCorrective action receipt

Countermeasure registration

ISIR/4M

Regular inspection registration

Expected Effect

Expected Effect-

01

Realizing a quality management system to create customer satisfaction

-

02

Securing quality consistency and stabilizing basic quality

-

03

Reducing defect rate and strengthening product competitiveness

-

04

Rapid and accurate response to customer needs

-

05

Securing customer reliability with quality information management

MATE-QMS Implementation Display

MATE-QMS Implementation DisplayPlease leave an inquiry

with your COMPUTERMATE specialist.